What is an EDIFACT CONTRL Message?

The EDIFACT CONTRL (CONTRoL) message acts as both a technical and functional acknowledgement for any EDIFACT message exchanged between customers and suppliers. When sent as a technical response, it indicates the receipt of the message along with its acceptance. It can also state the approval or rejection of the previously submitted interchange and a detailed list of errors as a functional response. They follow the EDI message standard UN/EDIFACT. Although CONTRL messages are not always mandatory, they are a vital message type for the electronic purchasing process in manufacturing industries.

The use of the EDIFACT CONTRL Message

There are two different styles of EDIFACT CONTRL message. Either as a technical response or a functional response.

A technical acknowledgement informs the recipient that the previous interchange has been received, whether it has been accepted, and references the message type and ID. These usually are far simpler than the more detailed functional acknowledgement. A functional acknowledgement indicates the same information as shown within the technical acknowledgement, but can also report on syntactic errors and break down the acceptance or rejection of each specific part of the previous message.

How does a typical EDIFACT CONTRL Structure look like?

An EDIFACT CONTRL message is sent in response to a received EDIFACT message as confirmation of receipt. These messages can be minimal in size, sometimes as little as three lines of code when a positive confirmation is sent. Once an ERP system receives a CONTRL message, the details held within can be cross-referenced to show the exact outbound message it relates to.

A typical CONTRL EDIFACT Message includes:

- Message header

- Details stating precisely which previously received message this acknowledgement relates to

- The acceptance or rejection code, at both interchange and message levels

- If a rejection is being sent, details of why this message (or part of the message) have been rejected

Processing of the EDIFACT CONTRL Message

Once an EDIFACT CONTRL message has been received, the EDI system will check the details held within the contents of the message to find which previously sent interchange this relates to. If it has been accepted, the customer knows that the contents and syntax of the message were correct and understood. If there are any rejections, specific details can be obtained to help the customer fix and resend this data in future interchanges.

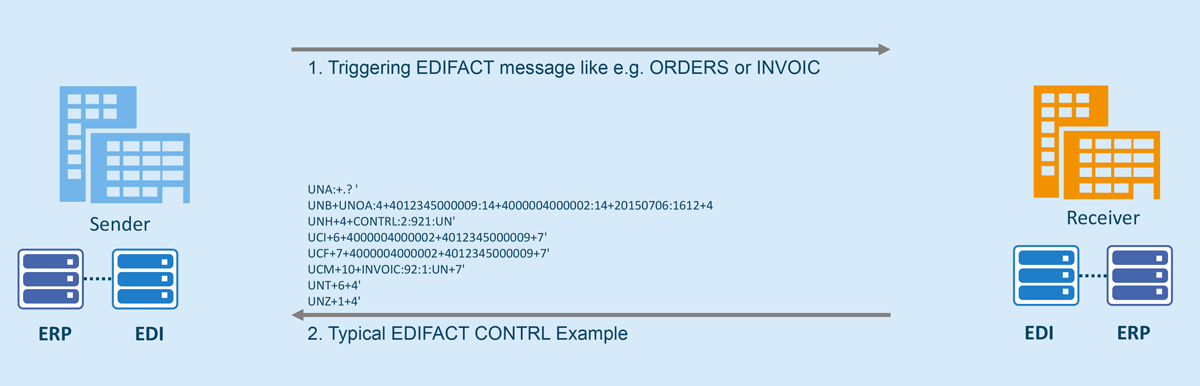

EDIFACT CONTRL Example in the EDI Workflow

An EDIFACT CONTRL message can be sent in response to any received EDIFACT message, to show whether it has been accepted, rejected, or partially rejected. Depending on the industry and the EDI guideline in place, the business may only require CONTRL messages for some EDIFACT messages and not all. Therefore there is no typical CONTRL example like with other EDIFACT messages.

What are the equivalents of EDIFACT CONTRL in other EDI Standard Formats?

VDA messages are still commonly used in the automotive industry. VDA APERAK (Application Error and Acknowledgement message), both 4937 and 4938, is used to acknowledge receipt of a message and highlight any issues. The ANSI X12 standard is widespread in the NAFTA region; for this standard, a 997 Acknowledgement would be sent out.

Typical Errors when using the EDIFACT CONTRL Message

- The acknowledgement is generated on the receipt of a valid or invalid message. This is the scenarios of a wrong alert.

- If the customer never received a message, no acknowledgement could be created. For such a scenario consider monitoring and alerting for non-events.

Benefits of the EDIFACT CONTRL Message

By using EDIFACT CONTRL messages, many different benefits can be gained:

- If parts of the message were rejected, these details are highlighted back to the user along with rejection reasons

- If only part of an interchange is denied, the accepted information can still be used and processed – this can also be reported back to the customer

- Rejected reasons can be imported into an ERP system and diagnosed against the previously sent message

Ensure stable use of EDIFACT CONTRL Acknowledgement files

SEEBURGER BIS Platform B2B/EDI capabilities are leaders in stability and reliability. For operating in a very reliable way we still recommend Control Acknowledgement files to speed up troubleshooting and to reduce the error rate exchanging information with external EDI Trading Partners outside your operational control.